- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

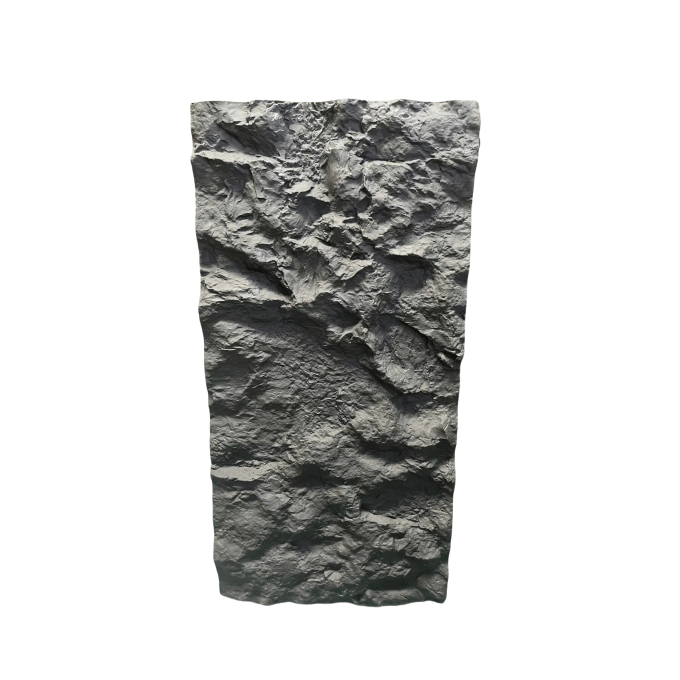

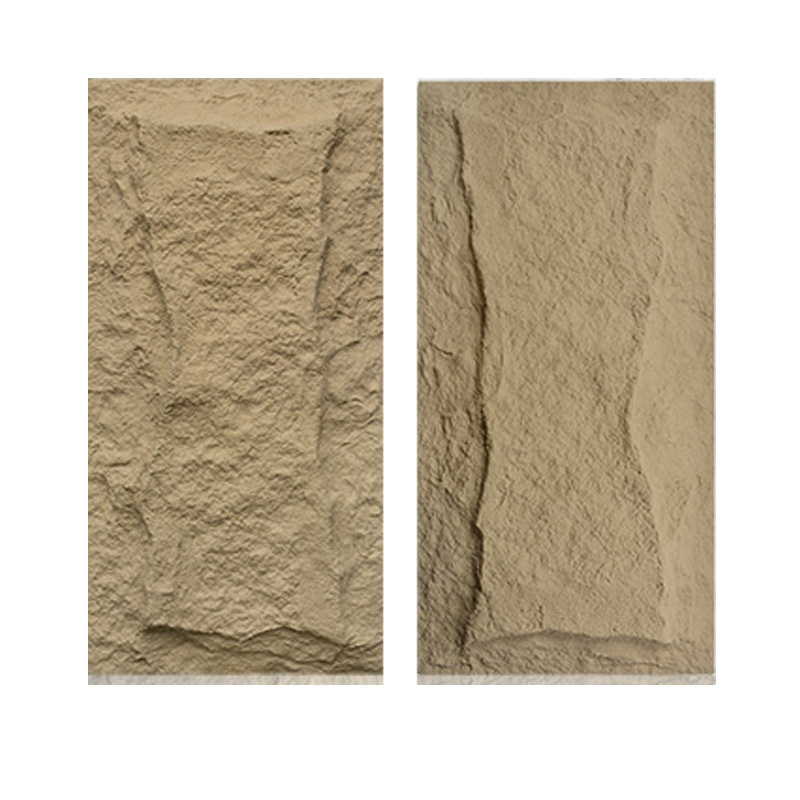

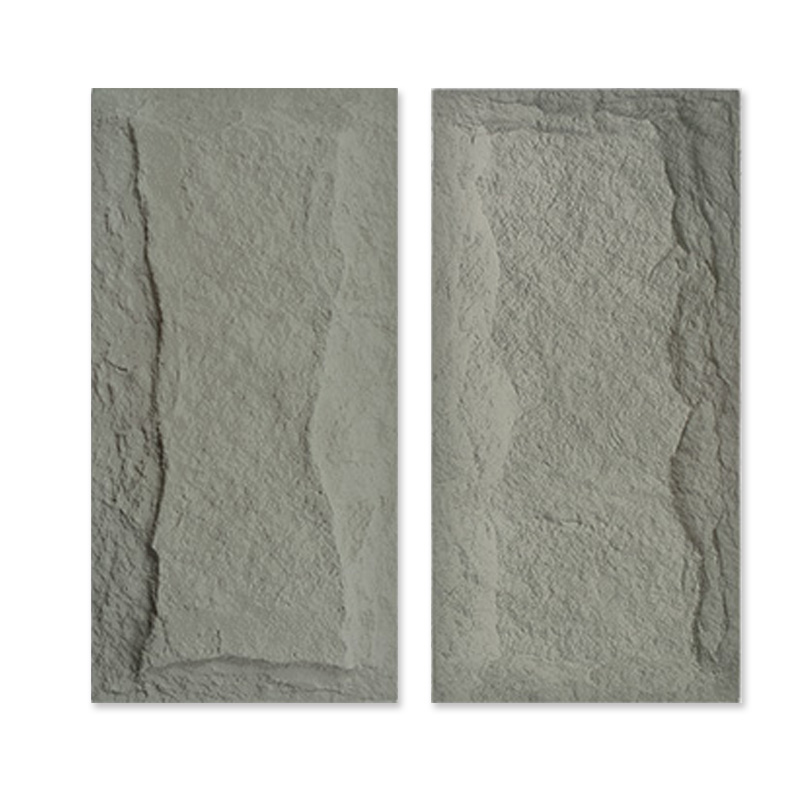

Stone Polyurethane Panels

Stone Polyurethane Panels are decorative elements used to mimic the appearance of natural stone walls. They are typically made from materials like fiber cement, concrete, or molded polyurethane. These panels are designed to be lightweight, durable, and easy to install.

Send Inquiry

Haining Xinhuang Decoration Material CO ,.LTD is a professional Stone Polyurethane Panels

factory

in China ,our Construction materials faux pu stone panel quality no.1 and service is best,it can use many place .

Industry-specific attributes

Project Solution Capability :graphic design, 3D model design, Cross Categories Consolidation, Others

Application :Hotel

Design Style :Modern

Stone Form :Cut-To-Size

Specification of Stone Polyurethane Panels

Warranty :More than 5 years

After-sale Service :Online technical support, Free spare parts, Return and Replacement,

Place of Origin :Zhejiang, China

Brand Name :HNXH

Model Number :PU-12

Stone Name :Stone Polyurethane Panels

Type :artificial Stone

Material :pu/polyurethane

Texture :similar with natural stone

Size :1200*600mm, 1200*300mm, customized

Thickness :20-100mm

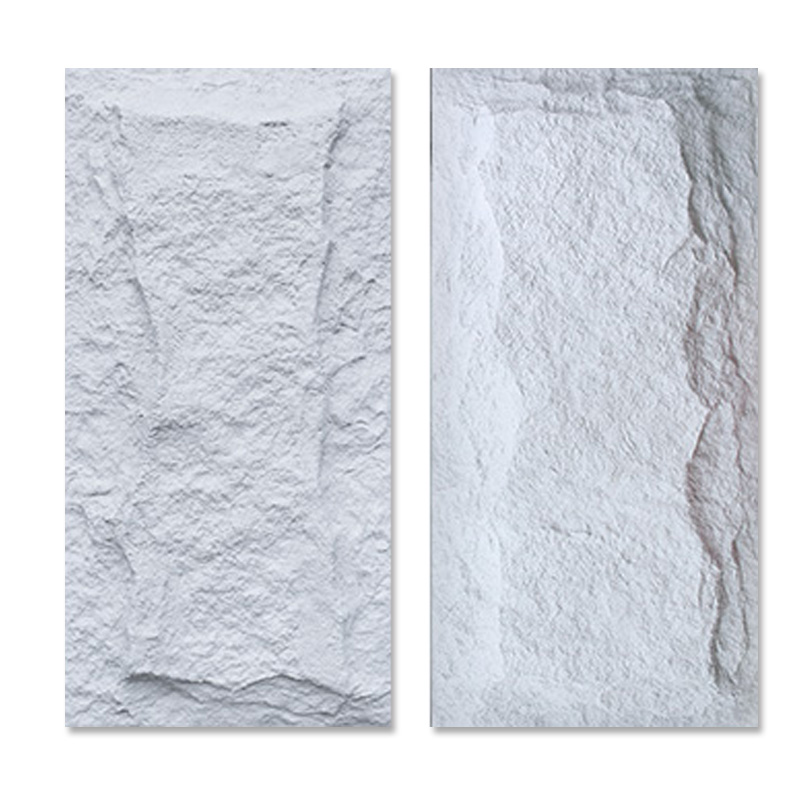

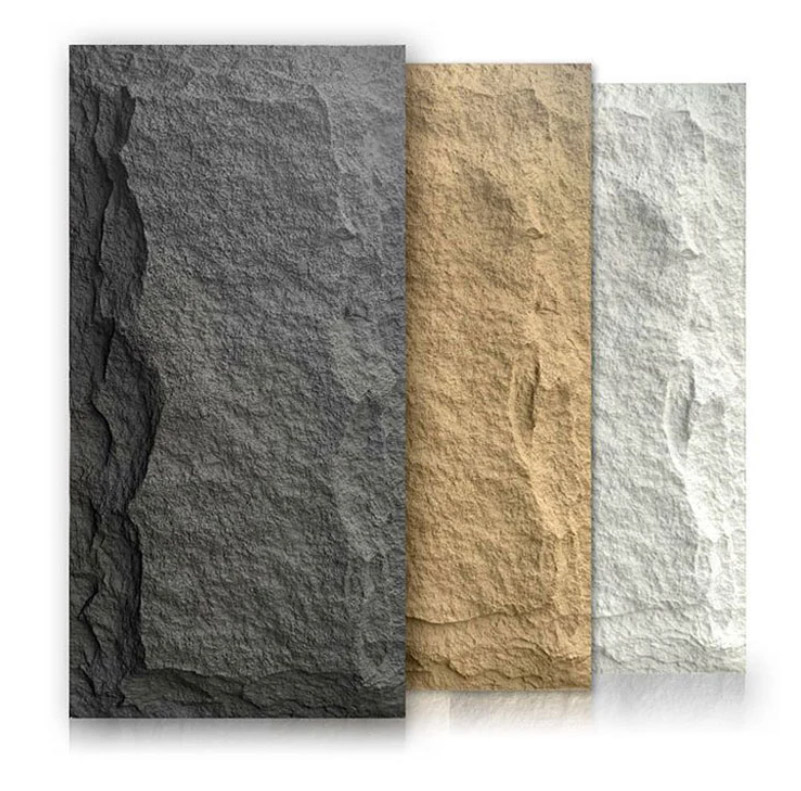

Color :white, dark, beige, grey

Outstanding Features: lightweight, fast installation, fireproof, waterproof, strong

Delivery Time: 3-10 days

Sample: Samples are presented free

What is Stone Polyurethane Panels?

Let’s analyze it from its original composition

The Chinese definition of “pu” is polyurethane, the full name of polyurethane

is the main chain contains repeated carbamate groups

It is the collective name of macromolecular compounds containing repeated carbamate groups in the main chain

It is composed of organic diisocyanate

or polyisocyanate with dihydroxy

or polyhydroxy compounds to form polyurethane materials

It has a wide range of applications and can replace rubber, plastic, nylon and other products.

It has the following characteristics.

(1) Long service life and cost reduction

(2) Temperature resistance from minus 20 degrees to high temperature 120 degrees

(3) Polyurethane products are non-polluting, non-toxic and tasteless.

It has been widely used in airports, hotels, building materials, automobile factories

Coal plant, cement plant, senior apartment, villa

Landscaping, colored stone art, parks, etc.

From the view of raw material, pu stone is more like a cross-border new material.

The familiar material is used to restore the real stone decoration material.

In terms of process, the raw material is pressed through the mold, and the color is applied inside the mold.

Usually the same type of appearance of pu stone will develop 2-4 pairs of molds.

All the mold shape are based on the real stone molded and made.

to achieve a more realistic splicing effect.

The surface is then protected by water-based environmental protection coating for exterior wall waterproofing.

What kind of Stone Polyurethane Panels products?

So what are the specific categories of pu stone?

All the culture stone shape pu stone has

For example, our traditional concept of

Great Wall stone, tile plate, flowing water stone, etc.

In addition there are more characteristic

Concrete cement board, mushroom stone.

The most distinctive style is the stone skin

The effect is close to the classic case

The effect is close to that of the uneven stone shape used in some classic cases

Performance characteristics of PU stone

We all know that the overall cost of the original rough stone is very high

In addition to the material itself, the construction needs to build a steel frame structure

and consume huge labor and material resources and in some areas of high floor height

There are also certain safety risks.

Then, Faux Stone Panels becomes the preferred alternative

– Multi-functionality –

It has passed professional waterproof, insect-proof, flame retardant and windproof tests

Can be applied to almost any flat substrate indoors, basement and outdoors

– Durable – the products are made of polymeric materials and

The product is composed of polymer materials and sprayed with multiple layers of high strength coatings

It is acid, sun and UV resistant for long lasting use

– Easy to install

The product is designed with an internal card structure with tongue and groove edges and pre-drilled seams.

Most of the work does not require inlay seams and can be installed directly with screws and gun nails